Whole Life SustainabilitY : New Building Life Cycles

form follows lifecycle

For projects were a new building is necessary, every stage of the architecture life cycle has to be considered:

A building is an ongoing process that consumes both energy and materials.

Earth systems are interconnected material processes that are the foundations of everything we make, ranging in timescale from the geological to the biological.

In between these are Human systems through which the built environment is made - extraction, fabrication, construction - and then unmade - disassembly, reuse, recycling and return to the Earth systems.

ecosystem thinking

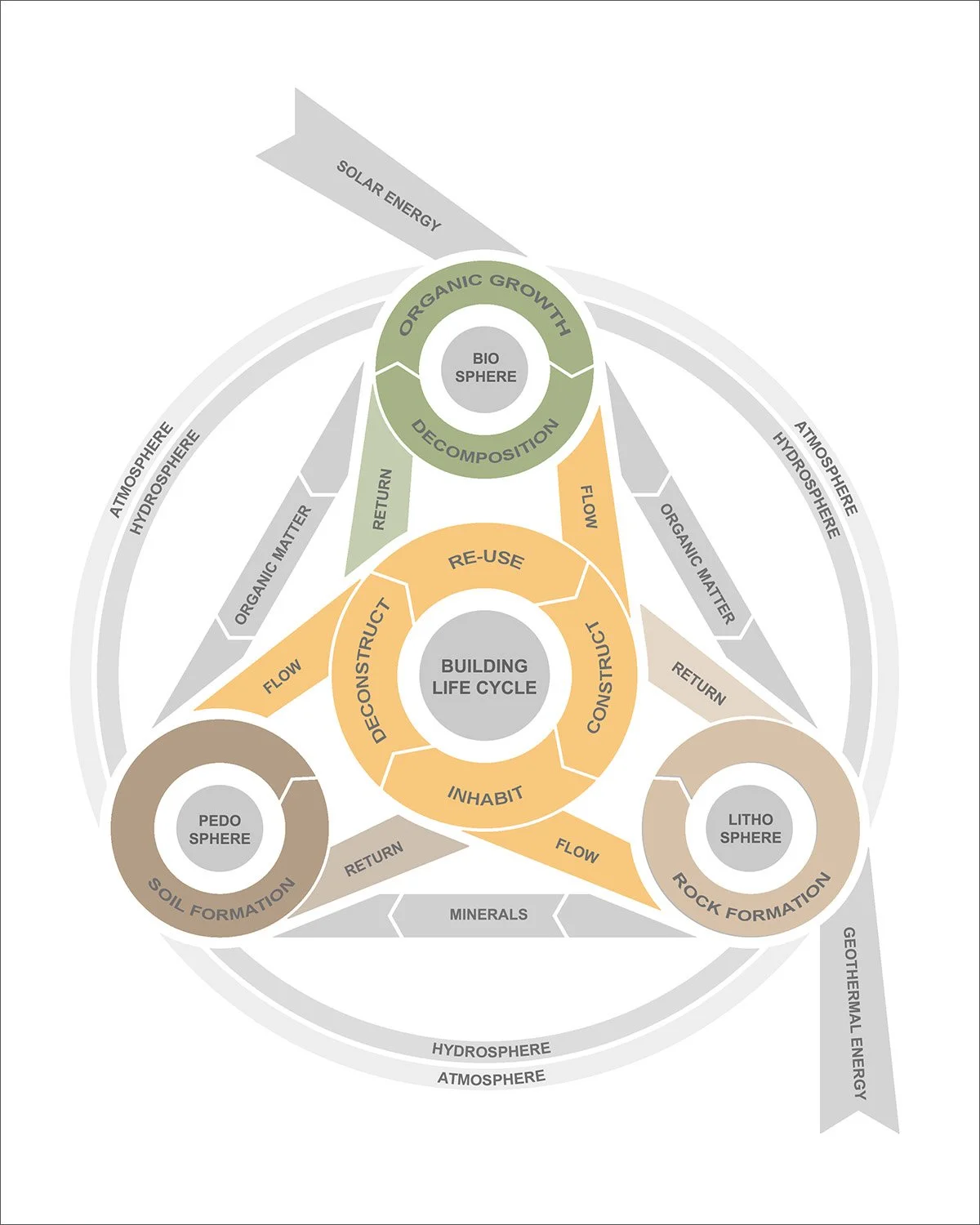

We developed this diagram to articulate the relationship between the building life cycle at the centre and key geochemical spheres - biosphere, pedosphere (soil and mud), and lithosphere (stone and minerals). The diagram focusses on these three spheres when talking about building materials because they relate more directly to components that are able travel into and out of the building life cycle and can be re-used – a process of exchange which is represented by the paths of flow and return.

These circular ecosystems encompass a vast range of processes and timescales – from coppiced chestnut (15-20 years) to soil formation (200-400 years) to fossilised sedimentary limestone (300 million years). This can inform how these materials are used in the building life cycle, which also includes a range of timescales – from furniture to replacement cycles to reuse of primary structure.

Resource + Extraction

Using materials from regenerative Earth systems - like timber and cork from the biosphere and earth from the pedosphere - places the emphasis on preserving their integrity throughout the building life cycle, so that they can be returned to Earth systems at the end-of-building-life. It is also crucial to manage our relationship with these systems in a way that does not adversely affect their health and regenerative capacity.

Using materials from systems that are effecitvely non-regenerative - like stone from the lithosphere - places the emphasis on maintaining circularity through re-use and re-fabrication.

MANUFACTURE + FABRICATION

We strive to create an 'Economy of Means', using strategies that:

Use relatively unprocessed materials that require low energy during manufacture and fabrication.

Minimise the total number of processes required to create a building envelope to meet current performance standards.

Avoid the creation of 'hybrid' materials, components or assemblies that cannot either be easily separated, recycled or returned directly to Earth systems.

ASSEMBLY + DISASSEMBLY

Construction can tend to be the stage at which materials become irretrievably muddled up and stuck together. Techniques that maintain 'reversibility' include:

Dry-jointed methods that enable 'Design for Disassembly' e.g. mechanical fixings that are visible and easily accessible.

Minimal use of hybrid construction such as reinforced concrete.

Minimal use of wet trades and finishes.

Longevity of the building structure is also a critical factor, and this can be encouraged through the design of 'loose-fit' structures.

REUSE + RECYCLE + RETURN

Most building components (and often buildings) reach an end-of-life scenario at some point.

Reuse: This is the most efficient method of retaining the material and energy embedded in a building component.

Recycle: Less desirable than reuse, but can reduce embodied carbon in the next life cycle e.g. recycled steel.

Return: Material that can't be reused or recycled can either be used to generate energy (W2E), returned to a regenerative earth system, or returned to non-regenerative systems as spoil.